All Respect to the Craftspeople: Handmade in Taiwan

Showing off a recently finished Log Lady fork

Where are your bikes made? It's a question that we get often and an answer that we're dang proud of: Taiwan. Now we're well aware that there might be an ill-informed knee jerk reaction to that answer, but the truth is that the island is the world's center for bicycle manufacturing for a reason and home to the greatest concentration of knowledge and building expertise on the planet. We're stoked that many riders and shops are realizing that it's not necessarily where your product is made, but rather who's making it that really matters.

It is in that spirit that we present you with an excerpt from the All-City Annual No 7, an article by our own Nick Paglia about his experiences meeting with and visiting our suppliers.

Non-drive stay of a Nature Boy being compared to large scale drawings to make sure it's just right

Handmade in Taiwan

Words & Photos: Nick Paglia

Working for All-City as the Product Manager has afforded me the opportunity to travel to many places around the globe. Unexpectedly, one of my favorite places to travel has been, and will continue to be, Asia. It is no secret that we do all of our frame and fork production in Taiwan and I’ve traveled there on three separate occasions over the past year and a half, all in an effort to help keep our process running smoothly. Taiwan is such a wonderful place to visit and the people, culture, food, and charm are inviting and intoxicating. When you leave, you instantly start thinking about your next chance to return.

We unfortunately live in a society that is largely focused on the commoditization of disposable products, many of which have “Made in Taiwan” or “Made in China” country of origin stickers. The import of sub-par products entering this country with those stickers affixed, has formed a stigma incorrectly associating the origin of manufacturing to quality. Part of the All-City philosophy is to deliver products that become a defining possession for its owner, something they own and cherish for a very long time yet our bikes are made in a country commonly associated with producing junk. So, how does that work? Simply put, what you’ve heard about manufacturing in Asia isn’t always true and I’d like to share my first-hand experiences while exploring what it means to be “Made in Taiwan.”

It is no accident that Taichung, Taiwan is the “Silicon Valley” of bicycle industry production. The great people, passion for cycling, and experience producing some of the most compelling product, make it a natural epicenter of cycling industry growth and innovation. As you drive through the narrow streets, lined with aqueducts and rice patties, you can’t help but run into several major industry partners like SRAM, FSA, Velo, and Transart, to name a few. Around every turn is a small CNC shop, paint facility, or tube forming specialist filled with experts at their chosen craft and niche. Entering a facility is like entering their home, where you are greeted with a warm smile, a cup of tea, and graciously offered a seat. Language barriers are quickly overcome, replaced with an unspoken yet interactive and mutually understood series of points and nods. You can gain a sense of what, how and why they do what they do just by observing body language, listening critically and looking intently.

A professional welder doing his thing on an unidentified frame

A seatube with our signature brazed-on seat collar before it is attached to the rest of the main triangle

All-City is fortunate to work with the best welders, fabricators, and painters that Taiwan has to offer. We have spent years establishing and bettering our relationships with key partners because of their technique and skill in both producing and finishing our bikes, frames, and accessories. Our partners understand our dedication to producing high performance and classically influenced products and help us turn our crazy ideas into reality. For me, getting to meet those talented folks within their walls, to experience their work, to see the look of passion and pride in their eyes as they showed me the frame or fork they worked on, was a life-altering and perspective-shifting experience.

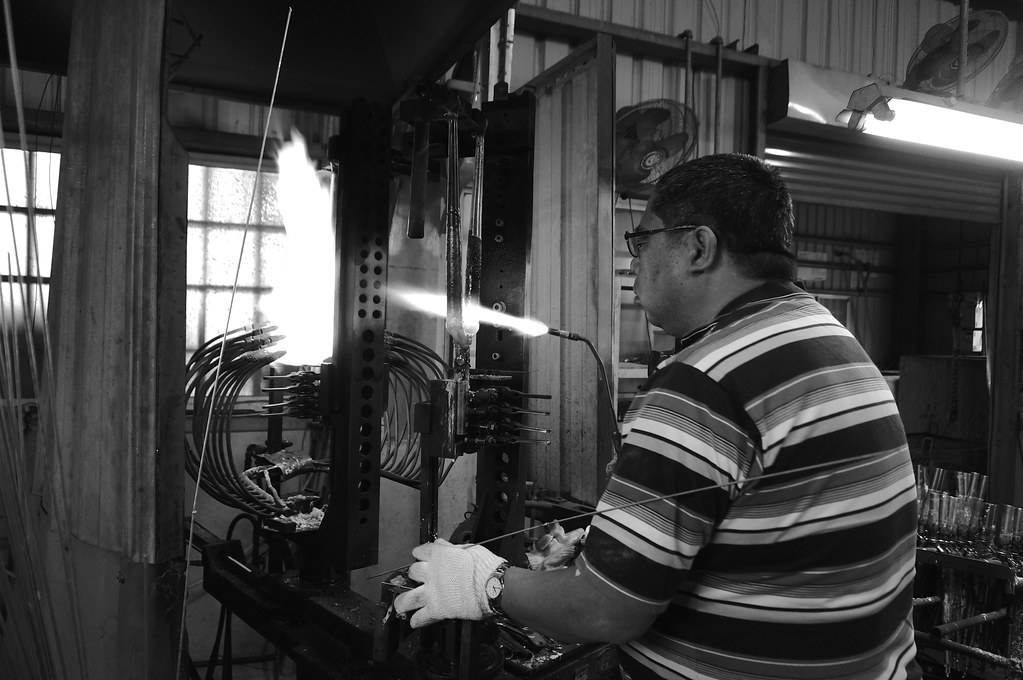

During my most recent trip to Taiwan in March of 2016, I made it my personal goal to document and understand more about the people behind our production. I really wanted to return from the trip with a more complete understanding of their story, and to leave our manufacturing partners with a better sense of how much we truly appreciate their skill, passion and expertise. I was greeted with carte blanche access to document many aspects of production, and that is where the pictures you see in the pages surrounding this article were born. One of the most impactful discoveries I made is the extent to which our frames and forks are completely, from start to finish, handmade. All of the forming, brazing, welding, fixturing, cutting, and clamping is done by hand and the employees performing the functions, most notably the welding staff across multiple manufacturers, has an average tenure of 15 yrs. The individuals working in all of our production facilities are long-standing artisans of their craft. Watching a frame being fine-tuned to spec on the alignment table, is a thing of beauty. There are no computers or robots carefully nudging frames into alignment, just years of skill and a masterfully trained eye.

I knew we had to do something to celebrate the support and partnership with our Taiwanese manufacturers, something more impactful and timeless than a write-up on the blog or sharing of photos through the social media channels. So, as of this model year, all bikes delivered in the second half of 2016 and beyond will come with our new “Handmade in Taiwan” stickers. Rest assured this isn’t just a clever marketing ploy, this is a genuine representation of appreciation and respect for the makers. We hope you will proudly display this sticker on your bike and that it becomes another signifier of quality, maybe even a point of conversation with your friends and family, as you enjoy your new All-City.

Rear end inspection and alignment

A rack of our Space Horse forks

Tea time

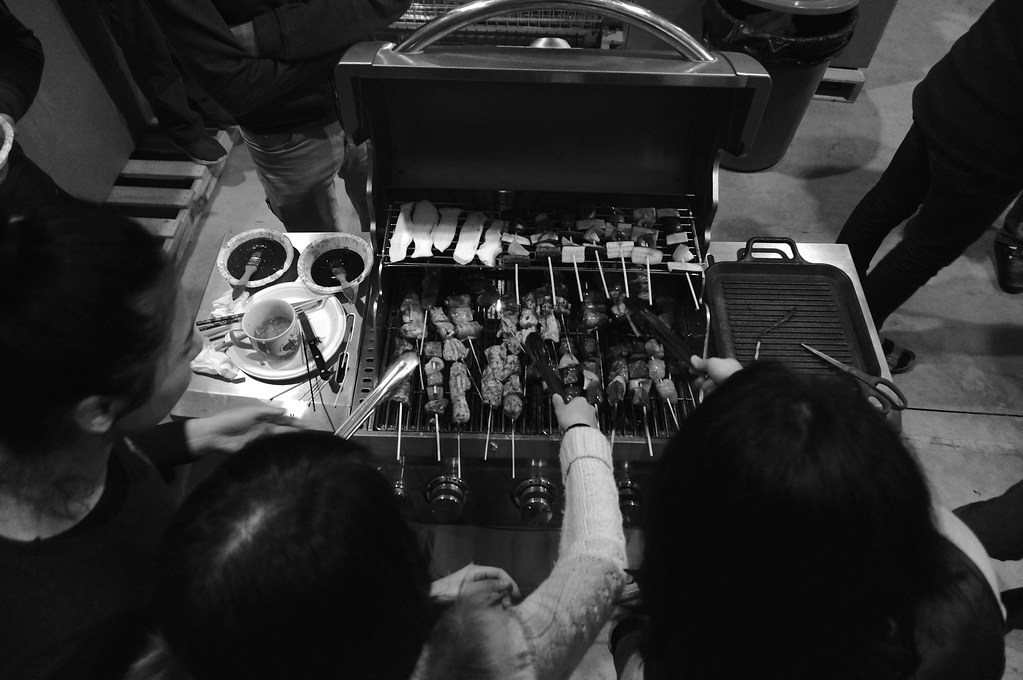

Staff lunch, way better than the stuff we usually eat

Top tubes with internal routing, ready to be welded into the main triangle and finished

Adam

Awesome Article, Great to see it!

Tim

Thanks for this. It’s good to see a brand take so much care, and I’m glad these workers appear to be treated fairly. Makes me even more proud of my Macho King!

Garth

If the lovely ride of my Big Block is any indication,carry on!

Meng

Nick, thanks for the look inside your partner’s facility and process. It’s great to humanize the handmade nature of the bike industry.

One tiny note—you used ‘impactful’ twice in the essay, and for such an unusual word to show up twice was kind of distracting.

Anyways, how do you square putting up the Handmade in Taiwan sticker with AC’s philosophy of not even putting model decals on the frame? Some might argue that the sticker has a really high contrast against light colored paint.

Jeff Frane

Meng,

In response to the sticker, we must affix both a warning sticker and a country of origin sticker by law to our bikes. If it was up to us, we wouldn’t put any stickers on it, but if we must, then we at least want to tell a bit of our brand story if possible.

Ganz

I acquired my Nature Boy by accident not knowing the brand for I was only looking for an affordable commuter and landed on this beauty for a bargain used price.

After dialing the cockpit and taking it on trail rides, I realized that I stumbled on a great find without even realizing it! And now I just finished reading Nick’s behind the scene write up and I gained this great deal of ownership pride having found this bike and riding it on weekend group rides where fellow riders admire its clean and noticeable craftsmanship. Now I wish I can have that “handmade in Taiwan” sticker and I’ll be more than proud to display it in my frame.

Reality

Yes, there is a reason Taiwan is where so many bikes are made. It’s because you can get frames made for cheap there. It’s a nice looking factory, but it is a factory. I’m disappointed to see that these frames, which you charge craftsman handbuilt prices for, are built this way. For this price I could get a De Kerf or a Rock Lobster or a high end Italian frame that spent its entire build life in one established craftsman’s hands. Another QBP product, like Surly, banking on a made-up pedigree.

Leave a comment

Commenting is not available in this channel entry.